Digital Image Correlation for material characterization

By Sofie Verstraete

Traditional methods to measure stretches in a material are an extensometer or strain gauges. These methods can measure the strain very accurately and reliably at the location and in the direction where they are applied. A more advanced technique, Digital Image Correlation (DIC), can be used to perform a full "full-field" strain measurement. The distortion pattern of the entire sample can be mapped here. With this technique it is also possible to measure strains in transverse directions, so that the Poisson ratio can be calculated.

Principle Digital Image Correlation

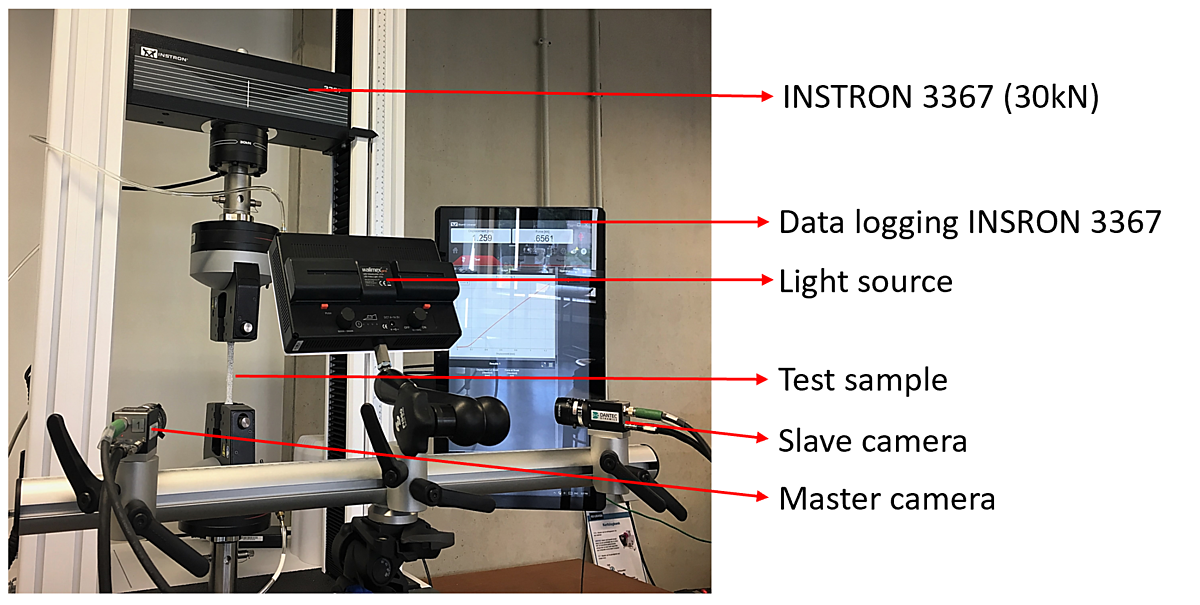

Digital Image Correlation (DIC) is a non-contact image analysis method based on digital grayscale. Displays can be measured in a 2D field by using 1 camera, or in a 3D field by using a 2nd camera. To perform a measurement in the 2D field, it is important that the camera is aimed perpendicular to the sample, since displacements out of the plane cannot be measured.

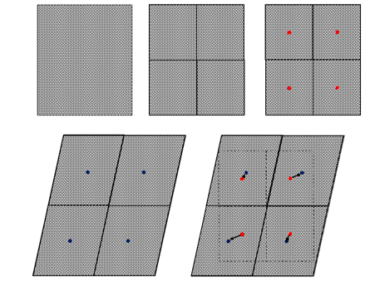

The principle of this measurement technique is based on the tracking of a point that was previously applied to the test sample. These points are placed on the part of the test piece to be examined. The dot pattern itself should be as random as possible and cover about 50% of the surface to get an accurate measurement.

During the measurement, the entire surface to be tested will be divided into different subsets, each of which contains a unique dot pattern. Before applying the displacement, a reference image is first taken. Within this reference image, the center will be defined for each subset. During the deformation, images are taken sequentially of the sample. Once the measurement is complete, these images are always compared with the reference image.

Each pixel within a subset is given a numerical value in the memory, depending on the gray value. Then a correlation algorithm is used to find this same subset in the distorted image.

Once the subset has been found in the distorted image, the locations of the centers are compared. From these displacements, a displacement vector can be defined for each subset. The local strains can then be determined from this displacement vector by means of the finite element method using 3 points.

Application DIC

The application of digital image correlation for a tensile test mainly shows its added value when using softer materials. When using an extensometer in an application where constriction occurs, the physical presence of the extensometer could influence the material behavior and thus an erroneous result could also be obtained. By using a non-contact measurement in this application, the elongation on the surface of the test sample can be measured during the entire test.

In addition to the use of DIC in standard tensile or compression tests, it can also be used in other applications. The speckle pattern can be applied to many geometries, which greatly increases the range of applications. An example of this is applying a v-notched (Iosipechu) shear test to determine the shear elongation of a material.